Go from raw materials to finished products in one step.

"Unbatched production" with FailSafe

When it comes to meeting the production demands of today's sophisticated coatings and adhesives, batch mixing systems have become a costly legacy technology with excessive waste and down time, too many steps, and imprecise measuring and metering.

That's simply too much risk, for both manufacturers and their customers, risk that the FailSafe system from Tremco Incorporated eliminates. The FailSafe system was designed from the ground up with best-in-class technology to improve the quality, consistency, repeatability and throughput of liquid products, all of which helps make them more profitable.

FailSafe's Patented Technology

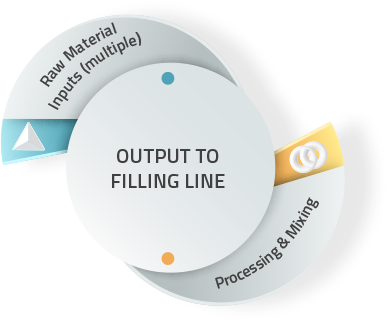

The FailSafe system provides "unbatched production" by replacing often-inefficient batch runs with precise, on-demand production, whether you need to fill a small order or large-scale output. This system's groundbreaking technology meters, controls flow and combines multiple liquid inputs into a mixing element in a continuous stream, then directly to the filling line.

With this just-in-time production, you get exactly how much you need when you need it, resulting in less waste, increased flexibility to meet customer demands, savings on raw materials, and faster inventory turnover.

Reliable, Repeatable and On-Spec Production

Traditional Batch Production

FailSafe Unbatched Production

In the unlikely event that the input or output deviates from specifications, the FailSafe system self-diagnoses the problem, stops production and notifies the operator that a change is required. There's no waiting to catch the problem during QA, no wasted material. The "unbatched" process leads to reliable and repeatable production without the risk of bad products reaching your customers.

With Fail Safe's unique technology, efficiency and quality increase dramatically, and the customer receives an on-spec finished product. Only the FailSafe system takes you from raw materials to finished goods in one continuous step!

Creating Better Liquid Products, Faster, for Your Customers

It's worth repeating — the failsafe system provides unmatched accuracy, quality and productivity to help you deliver state-of-the-art liquid products to your customers.

Its many benefits include:

- A continuous flow from input of raw materials to output of finished goods to the filling line

- Optimized product performance at reduced cost due to the ability to hold tight tolerances

- Fast, continuous mixing with no need to stop for QA

- Material flexibility – FailSafe is the perfect choice when you're working with reactive or moisture-sensitive materials, or have a series of short custom runs

- Higher productivity due to minimal maintenance, less and easier cleaning, and the ability to quickly change materials

- Less production equipment required, such as tubs and paddles

- Reduced operator labor

- Modular system design that is scalable to production demands

- Batch sizes can be varied and smaller than traditional production systems require

Producing over one million units a year; helping save lives

The FailSafe system is a production workhorse. One installation, for example, has produced three million units of a multi-component coating in just three years – one million-plus annually – with only three brief periods of unscheduled maintenance. This is a testament to the quality design and manufacturing of the FailSafe system and to conducting regular system inspections and routine maintenance.

In another, extremely sensitive application, the FailSafe system will produce three-component, moisture-sensitive intumescent coatings used for fire protection. Moisture must be purged during manufacturing and measures implemented to quickly remove any moisture that accidentally intrudes; if moisture slips through the QA process, it may only become apparent much later, when the product fails in a potentially life-threatening situation. With the Failsafe system, materials are not handled or exposed to air/moisture during production. Intumescent coatings help contain building fires, helping keep countless people safe; we're proud that the FailSafe system is relied on to produce something so important.

A strong heritage

The FailSafe system was developed by Tremco Incorporated, a leading manufacturer of roofing solutions and services as well as sealants and other waterproofing solutions. In business since 1928, we have the resources in place to ensure that the FailSafe system will produce for you.

In industries like aerospace, automotive and construction, the demand for liquid adhesives and coatings has never been higher, and it's growing quickly. Only the FailSafe liquid production system combines the accuracy, efficiency and control needed to meet their high-volume needs.